Cutting Applications

Production Methods offers many different types and styles of cutting applications.

From basic cutting applications to custom designed cutting applications, we are here to help you fulfill the designs your products require.

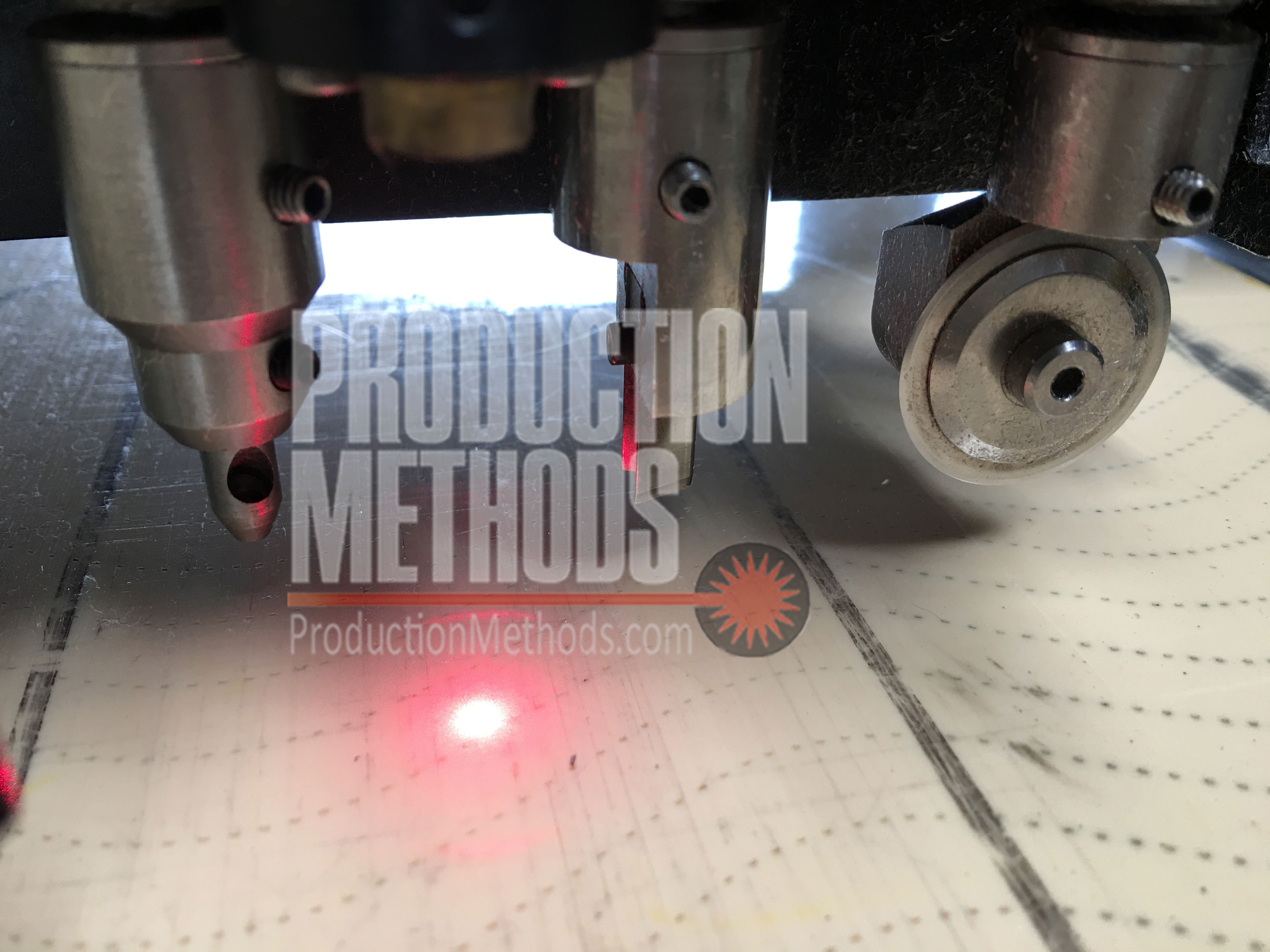

- Drag Knife or Tangential Knife cutting can also be used on most materials with excellent results. This tool utilizes a small (6mm)-carbide blade, which slices the material. This tool can be used to cut dry or Pre-preg Composites including Fiberglas, Carbon, Graphite, and even Kevlar as well as industrial fabrics such as vinyl, Weblon, and nylon. These knives can also be used to cut heavy plastics with tremendous accuracy. Notches, perimeter cuts, and interior cuts can be made with ease. These knives can yield accuracy of better than +/- .015″ in many cases.

- Wheel Knife or Round Knife cutting can be used on most materials with high speed and excellent efficiency. This tool utilizes a small (28mm or 45mm) diameter blade, which shears the material. Sometimes referred to as OLFA or KAI blades these small wheels offer speed and flexibility. They can be used to cut dry or pre-preg Composites including Fiberglas, Carbon, Graphite, and even Kevlar as well as industrial fabrics such as vinyl, Weblon, Acrylic, and Nylon. Notches, perimeter cuts, and interior cuts can be made with ease. Notching can also be accomplished with a separate notching tool. Most apparel fabrics can be cut with these tools.

- Laser cutting can be used wherever a sealed edge is needed. Anytime a woven, non-coated, man made material is cut fraying can occur. However with a laser, pieces cut from man made materials can be sealed in most cases to reduce the chances of fraying before the product is finished. Although not necessary on all products, this process can be a tremendous help to problem materials such as dry Fiberglas, Filtration goods, and nylon.

- Custom Applications can also be developed, such as glass cutting, box making, Glue Application, and Stringing machines. This is just the tip of the iceberg in terms of what we have done for our customers.

Production Methods buys used equipment to refurbish and resell to new and existing customers. To learn more visit our Used Machine Procurement page.

Production Methods sells and maintains some of the most common cutting machines available. To learn more visit our Cutting Machines page.

Production Methods buys and sells parts for the machinery we sell and maintain. To learn more about buying parts visit our Supplies page or for selling used parts visit our Parts Procurement page.